Workflows in the manufacturing industry are often complex. Production facilities, purchasing, sales, HR divisions, warehouses, and supplier connections are just a few of the many things that need to be handled.

The Industry 4.0 era, which is quickly moving toward Industry 5.0, has rendered obsolete or manual methods for managing operations, clients, or procedures ineffective.

The only way to maintain their industrial enterprises’ relevance, productivity, and competitiveness is through digital transformation.

Furthermore, without technological innovation, contemporary manufacturing businesses would not be able to offer a meaningful employee and consumer experience.

In other words, business applications are essential, and even manufacturers have come to this realization.

Examples of these duties include inventory management, work order creation, project progress monitoring, sales, production, and dispatch reporting, among many more.

Manufacturers are aware of the necessity of utilizing centralized platforms that are easily available from any area of their manufacturing facility or production sites to link their processes, people, and stakeholders.

This is where manufacturing-related mobile app development services comes in useful.

Manufacturing applications provide strategic and outcome-based benefits, ranging from enhancing productivity and departmental cooperation to facilitating data-driven decision-making with real-time data accessible.

We will cover all the important topics, such as kinds, advantages, prices, and utilization, associated with manufacturing mobile app development in this post.

Introducing Manufacturing in the World of Mobile Apps

Our everyday lives now revolve around mobile applications. Manufacturing is one of the industries that smartphone applications have revolutionized, along with entertainment and healthcare. Mobile apps, which offer simple accessibility, increased communication, and flexibility, have completely changed the production processes. The firms have been able to increase production, maintain greater quality control, and streamline their daily operations thanks to these apps.

- Enhanced flexibility and mobility

- Enhanced intercommunication and cooperation

- Effective supply chain and inventory control

- Real-time production tracking and monitoring

- Increased security and adherence

What benefits can mobile apps offer in the manufacturing industry?

The following are the main advantages that manufacturers may get from using mobile app solutions in their company:

Reduced Duration of Product Life Cycles

Manufacturers may guarantee quicker cooperation and communication with the use of mobile apps. Their capacity to react quickly to market needs is boosted by this.

Software development life cycles may be shortened by using mobile applications to automate and streamline a variety of production-related tasks.

Real-time equipment maintenance notifications are another feature of manufacturing applications. This greatly reduces the likelihood of expensive malfunctions and downtime that might interfere with production cycles.

Enhanced Production Effectiveness

Employees may quickly access vital information on their mobile devices whenever needed with the help of manufacturing applications.

They may make choices pertaining to production without having to wait for data or reports from other departments thanks to this real-time information.

Better production processes result from this information flow and other elements of manufacturing applications that increase productivity.

Training courses, gamification-based staff training modules, and readily available video lessons may all be accessed through mobile applications.

Improved Control Over Stock and Logistics

There are several advantages to using mobile apps for inventory management in the industrial industry.

- Inventory management and tracking in real-time

- Automatic reordering tools lessen the chance of stockouts

- Using prudent procurement practices to prevent stock surpluses

- Controlling the logistics, carriers, and distribution of shipments

- Enhancing supplier communication with a mobile app

- Enhanced dependability in completing orders with GPS-enabled shipping tracking applications

- Clearly visualizing and optimizing transportation fleets and supply routes

Also read: How to grow transportation business with logistics app development

Data-Informed Judgmentation

Manufacturing applications with real-time data analysis features enable experts to track and pinpoint inefficiencies in production processes.

Manufacturing applications give decision-makers the ability to collect and analyze data in real-time and make well-informed decisions based on actionable insights.

Manufacturers may now make rapid, insight-based, and rational judgments about their production activities since data-driven analytics removes subjectivity and decision bias from their actions.

Address Possible Quality Problems

All quality control indicators are taken into consideration thanks to mobile apps for quality checks and inspections.

During inspections, quality control teams can record all the criteria they need to verify on a checklist that is stored in their mobile applications.

It enhances surveillance and elevates inspection. Mobile apps can improve prospect discovery by providing more accuracy and balance in manufacturing.

Empowering Relationships with Customers and Suppliers

Big businesses that offer their clients apps maintain a constant line of communication with their clientele. Correct?

How can producers cultivate enduring bonds with their suppliers and clients?

The first requirement is to communicate honestly and openly. Customers are more likely to remain satisfied and devoted to your company when they receive timely alerts, tailored offers, loyalty points, membership advantages, and a full visualization of their interactions with your manufacturing unit.

In addition to live assistance, customer service can also be offered through applications that have embedded self-help videos, demo videos, instructions, documentation, reports, and digital catalogs.

Cut Operating Expenses and Release Workers

One of the main operating expenses associated with production is employee salary.

You should reevaluate your existing operational strategy if an employee can complete three activities a day without automation and five tasks a day thanks to automation facilitated by mobile apps.

If administrative duties aren’t automated, workers will work longer hours and lose important time on monotonous chores.

Therefore, by using applications to automate repetitive administrative operations, firms may save labor expenditures on employee time and lessen employee strain while freeing up staff to concentrate on higher-value and core production duties.

How Can Mobile Apps Help Manufacturers Manage Important Processes?

Specialized applications called manufacturing apps are created to help manufacturing companies modernize their digital operations. These applications often include targeted features that can assist manufacturers in automating and optimizing their primary administrative chores.

They are specifically designed for a certain kind of manufacturing sector. The features assist manufacturers in eliminating their main pain spots and gaining more speed, precision, and efficiency in their day-to-day operations.

Mckinsey places a strong emphasis on enabling digital transformation through essential mobile applications for managers, operators, and technicians.

Production Management App for Manufacturing

Increasing manufacturing output requires improving operational models. Better operational models for the manufacturing industry may come from the digital revolution manufacturing applications bring about.

Actually, according to a report conducted by Gartner Research, 67% of CIOs, their top goal for digital transformation is to improve operational models.

Manufacturing companies may plan their production schedule, monitor production progress, and maintain communication among team members by using production monitoring applications that provide real-time access to production data.

Managers can increase production operations’ efficiency by utilizing manufacturing.

Inventory Management Applications For Manufacturing

Manufacturers can trace the movement of completed goods and raw materials from production facilities to warehouses and distribution networks with the use of mobile app development services (and vice-versa).

From their app, managers may monitor the supply chain. With GPS-enabled applications, they can also see where their merchandise is located. Their inventory status (transit inventory, warehouse inventory, inventory under process, returned items, and more) is accurately depicted by this data.

Multi-location inventory management functionalities are also included in manufacturing inventory management apps. Stock audits can also make use of mobile apps that have barcode scanning built into them.

Digital checklists make it possible to monitor the warranties, stability, and equipment state (wear and tear) of assets (forklifts, machines, etc.).

Also read: How eCommerce is changing the future of warehouses

Manufacturing Apps for Generating Barcodes

Workers in the production facilities frequently have to keep track of or find certain inventory, replacement parts, or equipment.

They can track every item in the production line, warehouse, or vehicle with the use of barcodes. This procedure is made simpler in the industrial sector by the use of barcode technologies.

Mobile app-enabled barcode solutions make it simple to create, scan, and authenticate any kind of barcode, which is advantageous for manufacturing companies of all sizes. (1-D, 2-D, Alphanumeric, Numerical, and Additional).

Manufacturing Applications for Database Access and Reporting

How simple will it be for all parties involved in manufacturing—employees, managers, supervisors, and management—if they can get work-related reports on their mobile devices with a few clicks?

Modules in mobile apps for the travel and transport development solution can be accessible based on admin permissions that have been specified according to authorization.

As a result, everyone with user permissions may access, read, and download reports that they are permitted to.

- Sales summaries

- Purchase histories

- Certifications for tests

- Material bills and dispatch reports

- Reports on inventories

- Reports on quality assurance

- Accounts Payable

- Reports on assets and equipment

- Reports on compliance

- Reports from suppliers

Manufacturing Supply Chain Management Apps

Supply chain disruptions continue to plague even seasoned manufacturing executives. Supply chain resilience may be increased and any weaknesses can be found with the use of mobile applications for SCM.

Suppliers, third-party carriers, distributors, and logistics teams are all brought together on one platform via these apps. These specially designed applications may assist manufacturers in maintaining control over their supply chain operations.

These apps can handle anything from supply vendor management to Procure-to-pay (P2P) operations, supply chain analytics, and shipping carrier and reverse logistics monitoring.

Also read: Why Blockchain development is a game changer for supply chain management?

Applications for Maintenance Management in Manufacturing

Preventing situations of machine breakdowns and downtimes requires the timely scheduling of plant maintenance operations, including predictive and corrective maintenance, as well as equipment testing.

The manufacturing applications can automatically schedule maintenance regularly and send out maintenance reminders to every department. T

hese programs provide the ability to assign work to maintenance teams and generate job sheets for plant maintenance. Reminder alerts can also be sent by the applications to the relevant departments.

Quality Control Apps for Manufacturing

Manufacturers may easily perform and manage quality control inspections with the use of mobile applications for quality assurance. With the help of the app’s checklists, quality control teams may carry out audits while also recording and sharing images and videos of the procedure. The applications offer the ability to identify problems and recommend fixes.

IoT-enabled Apps for Manufacturing

By 2025, the industrial Internet of things (IoT) app market will have grown from 4.4 billion dollars in 2021 to 22 billion US dollars. Why? Nowadays, manufacturers are taking the advantages, effects, and use of IoT, bots, and mobile apps in their business verticals very seriously.

Through the integration of sensors and data, these applications may monitor a range of characteristics, including employee behaviors, ambient conditions, and equipment functioning, hence potentially leading to better workplace safety.

Real-time mobile notifications may be delivered to the appropriate staff in the event of an accident or incident, allowing for quick intervention and resolution. The process of developing an IoT mobile app gives managers and supervisors complete visibility into activities taking place on the floor.

Manufacturing processes may be remotely monitored and managed through the use of mobile applications and IoT-connected equipment.

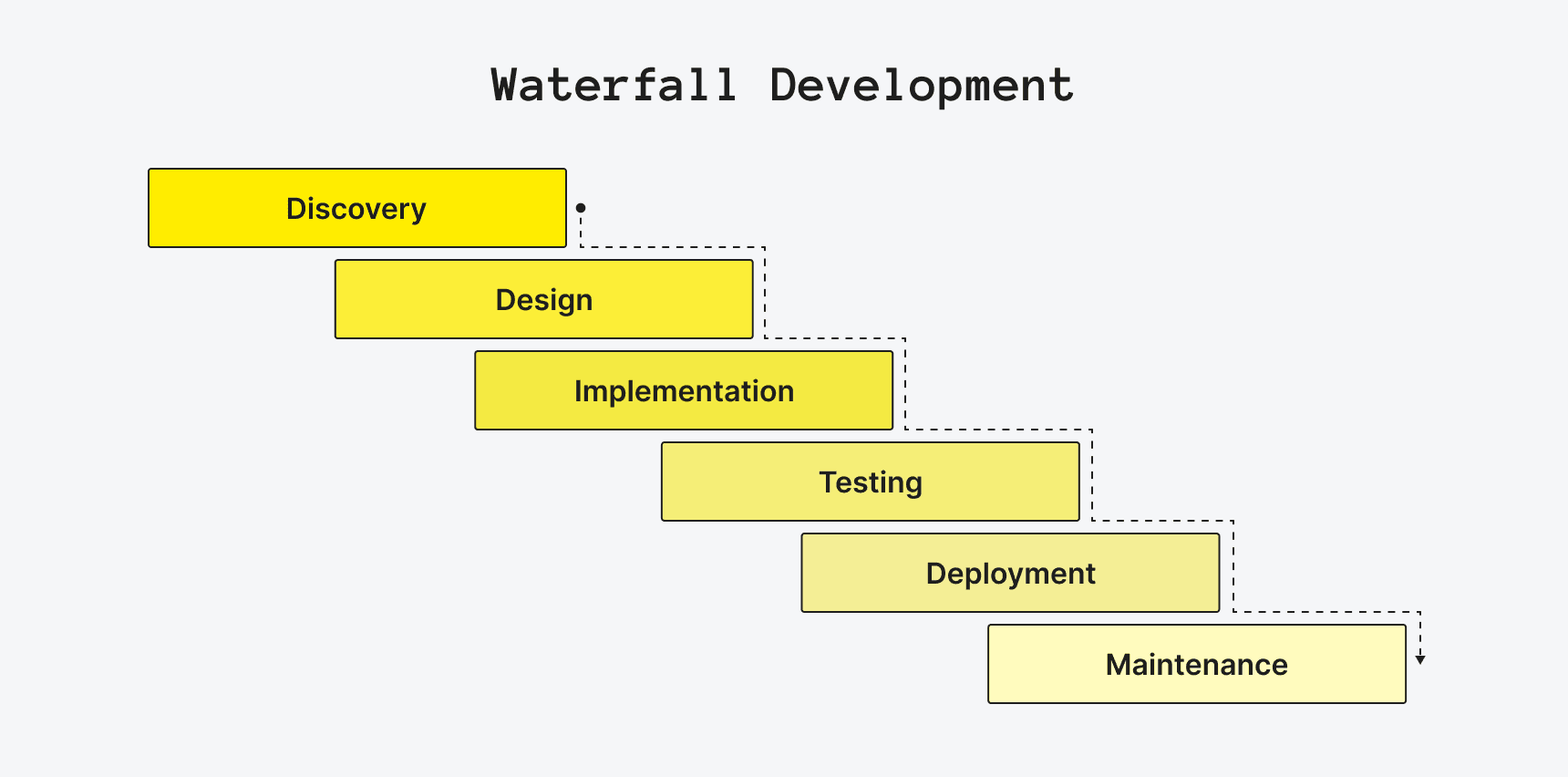

Development Models To Choose From For Manufacturing Apps

Choosing the right development model for manufacturing apps depends on factors such as project complexity, flexibility requirements, team expertise, and the need for continuous updates.

The below-mentioned models have their strengths and weaknesses, so it’s important to align the choice with your specific project goals and organizational capabilities.

1. Native Apps

Applications built specifically for a particular platform (iOS or Android) using platform-specific languages and tools (Swift/Objective-C for iOS, Java/Kotlin for Android). They offer optimal performance and seamless integration with device features.

Best For: Apps requiring high performance, access to device-specific features, and a superior user experience.

Progressive Web Apps (PWAs):

Web applications that use modern web capabilities to deliver an app-like experience on any device. PWAs are accessible via a browser and can work offline, send push notifications, and load quickly.

Best For: Cross-platform accessibility, fast deployment, and reducing the cost of development while providing a near-native app experience.

Web App Development:

Development of applications that run within a web browser using technologies like HTML, CSS, and JavaScript. These apps are platform-independent and can be accessed from any device with a web browser.

Best For: Projects requiring wide accessibility, easy updates, and lower development and maintenance costs.

AR/VR Development:

Creating applications that leverage Augmented Reality (AR) and Virtual Reality (VR) technologies to provide immersive experiences. These apps often require specialized hardware and software to create interactive and engaging environments.

Best For: Innovative projects in fields like gaming, education, training, and real estate, where immersive and interactive experiences are essential.

Internet of Things (IoT):

Development of applications that connect and interact with IoT devices, enabling communication between devices and central systems. IoT apps can monitor, control, and manage smart devices through a unified interface.

Best For: Projects focused on smart homes, industrial automation, healthcare, and other domains where interconnected devices and real-time data exchange are critical.

Some other development models include:

Agile Model:

An iterative and flexible approach that divides the project into small, manageable units called sprints. It allows for regular adjustments based on feedback, making it ideal for projects with evolving requirements.

Scrum:

A framework within Agile that focuses on delivering small increments of the product in fixed-length iterations called sprints. It involves roles like Scrum Master and Product Owner, and ceremonies like daily stand-ups, promoting teamwork and continuous improvement.

DevOps:

A practice combining development and operations to shorten the development lifecycle and deliver high-quality software continuously. It emphasizes collaboration, continuous integration, delivery, and automated testing, ideal for projects needing fast, reliable updates.

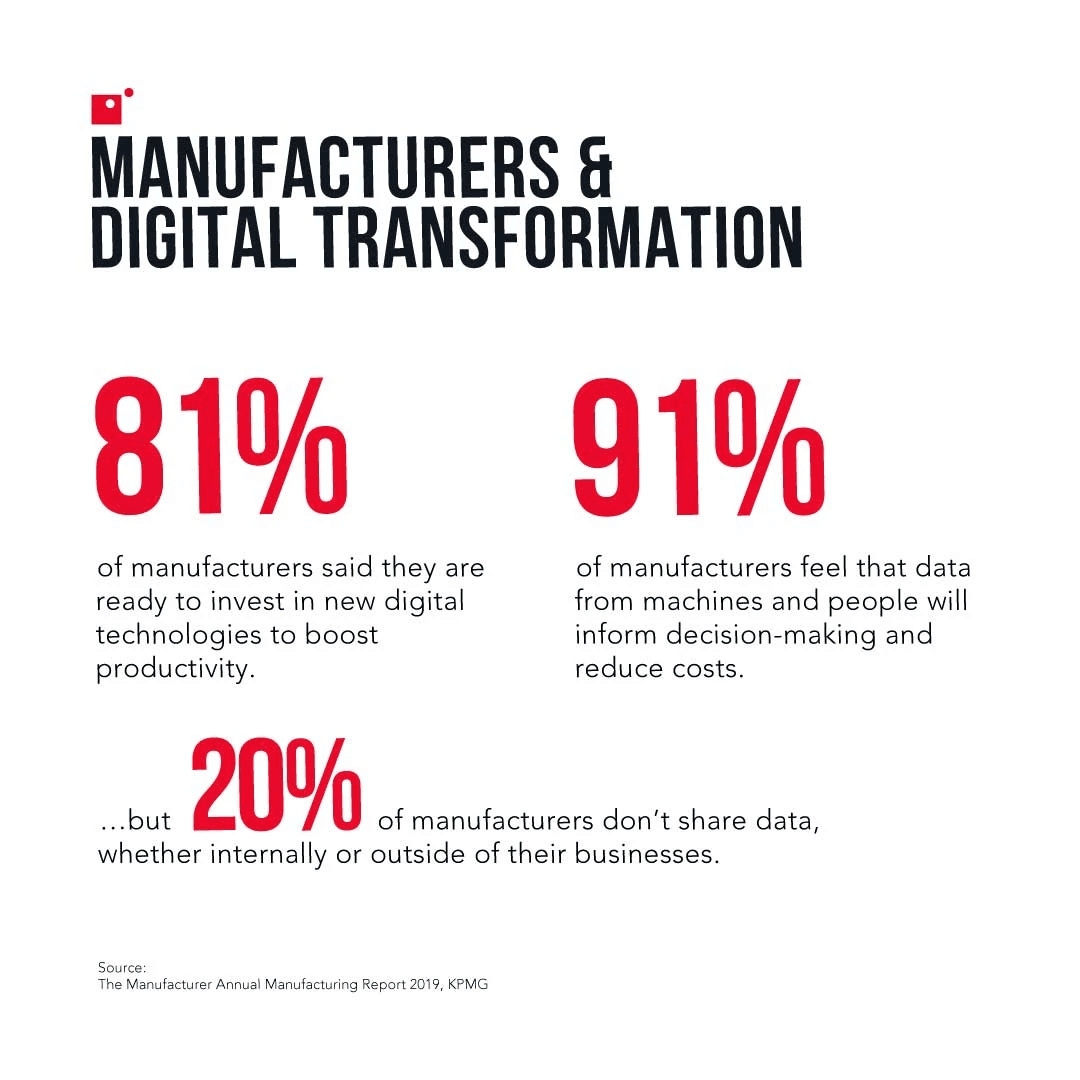

Statistics Ruling The App Development Usage in the Manufacturing Industry

- Manufacturers using mobile apps report a 44% increase in productivity, as apps streamline operations and improve communication.

- 67% of manufacturers have implemented mobile apps to enhance operational efficiency, reducing downtime and accelerating decision-making processes.

- Companies adopting mobile applications for manufacturing operations experience an average cost reduction of 25% through optimized resource management and minimized manual errors.

- 58% of manufacturing workers use mobile apps for task management, training, and real-time data access, leading to higher job satisfaction and performance.

- 72% of manufacturers use mobile apps for quality control and compliance checks, resulting in a 30% reduction in defects and non-compliance issues.

- 55% of manufacturers utilize IoT-enabled mobile apps for predictive maintenance, cutting unplanned downtime by up to 50%.

- Mobile apps improve supply chain visibility and management, with 60% of manufacturers reporting enhanced tracking and a 22% improvement in delivery times.

How To Choose The Best Mobile App Development Company For Manufacturing Business?

Selecting a custom software development company for your manufacturing business is like constructing a strong aeroplane. You want an expert pilot (an experienced partner) who is familiar with the environment (your industry) and makes use of the best tools (technological know-how).

Before transferring the project, make sure the mobile app development partner has the following metrics:

Technology Proficiency

It is essential to commit your project to a competent app development partner, just as you would give your life to a trained pilot. Seek a business that has developed apps for both iOS and Android or for the platform you require. Make sure they build native or hybrid apps using excellent frameworks.

Domain Expertise

Find a partner who is knowledgeable about your sector. They will help with strategic issues like revenue models and regulatory compliance in addition to helping you avoid development errors.

Ratings and Portfolio

Examine the company’s reviews, case studies, and portfolio on reliable websites. This provides you with information about their background and standing.

Prices and Expenses

Recognize the pricing structure, whether set or hourly, and make sure that the manufacturing app development cost includes everything from development to maintenance.

Reasonable Recommendations

Watch out for businesses that slavishly copy the success of others. Make sure they provide unique ideas and provide a detailed explanation of the technology they have chosen.

Personalization Choices

To meet the specific requirements of your company, choose custom app development. Manufacturing organizations may benefit from custom applications that provide enhanced user experience, increased efficiency, enhanced security, market segmentation, and enhanced brand image.

Final Thoughts

To create a manufacturing app for your sector, you’ll need to work with a mobile app developer with experience, such as DianApps. Our team has expertise in creating low-cost, high-impact mobile applications that can propel your manufacturing firm to new heights with the advantages of well-thought-out, well-executed manufacturing apps.

We will walk you through every step of the process, from identifying the most important features for your app through user research to resolving particular functional issues with mobile apps, existing system integration requirements, and selecting the best app development platform.

Leave a Comment

Your email address will not be published. Required fields are marked *